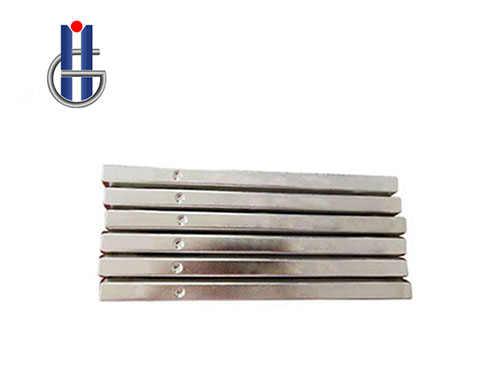

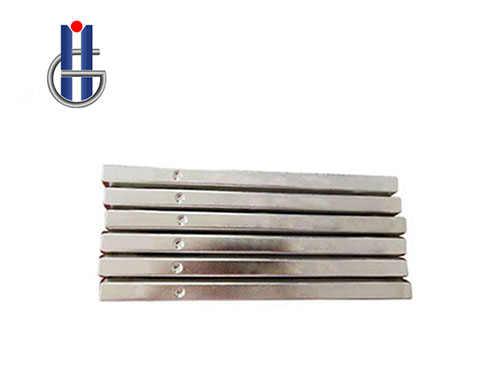

A

lead-free tin solder bar, also known as lead-free solder, is a type of solder that does not contain lead, a toxic heavy metal that was commonly used in traditional solders. Lead-free solder has become the standard in many industries, particularly in electronics, plumbing, and various other applications, due to health and environmental concerns associated with lead exposure. Here's some key information about lead-free tin solder bars:

Composition: Lead-free solder bars are typically composed of various metals, with the primary components being tin (Sn) and a combination of other metals such as copper (Cu), silver (Ag), bismuth (Bi), or antimony (Sb). Common lead-free solder alloys include Sn-Cu, Sn-Ag-Cu, and Sn-Bi.

Melting Point: The melting point of lead-free solder is generally higher than that of lead-based solder, which can affect the soldering process. It's important for soldering equipment and techniques to be adjusted to accommodate the specific alloy used.

Environmental and Health Concerns: The transition to lead-free solder is primarily driven by concerns about the toxicity of lead and environmental regulations restricting its use. Lead is a potent neurotoxin that can have severe health effects, especially in occupational settings and during electronic waste disposal.

RoHS Compliance: The Restriction of Hazardous Substances (RoHS) Directive in the European Union restricts the use of hazardous substances in electrical and electronic equipment, including lead. Lead-free solder is essential for products to comply with RoHS regulations.

Applications: Lead-free solder is used in a wide range of applications, including electronics manufacturing (soldering of printed circuit boards), plumbing (soldering of copper pipes), and various other soldering tasks in industries where lead contamination is a concern.

Strength and Reliability: The mechanical and electrical properties of lead-free solder can differ from those of traditional lead-based solder. These differences can impact the long-term reliability and performance of soldered connections, making it important to select the right alloy for the specific application.

Soldering Equipment: Lead-free solder requires soldering equipment that is designed to handle the higher melting temperatures and specific characteristics of the alloy used. Soldering irons and reflow ovens, for example, must be suitable for lead-free soldering.

Solder Flux: The choice of flux is crucial when working with lead-free solder. Flux helps remove oxides and contaminants, ensuring good wetting and bonding. Some lead-free solders require specific types of flux.

Training and Technique: Soldering with lead-free alloys may require adjustments to soldering techniques due to the different properties of these alloys. Adequate training is essential to ensure reliable solder joints.

Lead-free tin solder bars have become the standard in most modern industries, promoting both environmental responsibility and improved health and safety conditions for workers. While the transition from lead-based to lead-free solder posed certain challenges, it has led to safer and more environmentally friendly soldering practices.

High Purity Tin Ingot: Crucial Applications and Benefits

High Purity Tin Ingot: Crucial Applications and Benefits

Pure Tin Ingot: Essential Material for Diverse Industrial Applications

Pure Tin Ingot: Essential Material for Diverse Industrial Applications

Unlocking the Potential of Pure Tin Bars: Essential Components for Diverse Industries

Unlocking the Potential of Pure Tin Bars: Essential Components for Diverse Industries

Lead Bar for Sale: Uses, Specifications, and Buying Considerations

Lead Bar for Sale: Uses, Specifications, and Buying Considerations